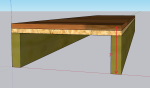

Doing a pressure treated sleeper floor that sits on top of a concrete slab for our addition to match the height of the existing house floor.

Currently in the process of laying down stone for the slab to be poured and then final grading.

![]()

The floor stackup requires 7" of height (2x6 5.5" + subfloor 3/4" + hardwood 3/4").

In other words, the goal is to have them pour it so that the top of the finished slab is 7" below the top of the existing hardwood floor.

![]()

However, the wet pressure treated lumber I've dealt with before from home depot usually runs wider than expected due to being wet.

As in a 2x6 that is expected to be 5.5" wide might come an 1/8" or more wider until it dries out.

How would you account for this?

How long would you have to wait for it to dry and shrink closer to the expected 5.5" of a 2x6 so that the new floor doesn't end up lower after it dries out?

Currently in the process of laying down stone for the slab to be poured and then final grading.

The floor stackup requires 7" of height (2x6 5.5" + subfloor 3/4" + hardwood 3/4").

In other words, the goal is to have them pour it so that the top of the finished slab is 7" below the top of the existing hardwood floor.

However, the wet pressure treated lumber I've dealt with before from home depot usually runs wider than expected due to being wet.

As in a 2x6 that is expected to be 5.5" wide might come an 1/8" or more wider until it dries out.

How would you account for this?

How long would you have to wait for it to dry and shrink closer to the expected 5.5" of a 2x6 so that the new floor doesn't end up lower after it dries out?