Thank you

@seharper Im glad the plan sounds thorough! Ive been learning so much, it feels like the accumulation of my learning up to this point.

Im happy to hear that you think it makes sense to mount the panel behind the door. Yeah, I wanted to do an out-swing door but then I realized it would make the door significantly more exposed. With the inswing door I have a little more protection of the doorway, since its recessed a few inches beyond the exterior surface of the wall. Figured I can always change the swing later on if I really want, but for now it seems to be OK. I will look into the QO816 panel, I didnt realize it was the same box size but now that I have the 6 space panel I can see how that works - If I had known that before I definitely would have ordered the 8 space panel.

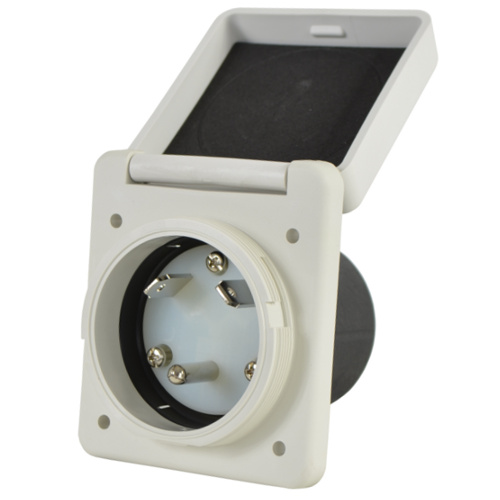

Panel-Inlet Compatibility Issue: I am looking at the 6 space panel I have right now and it says "main terminals suitable for No. 8 to No. 1 wire or 1/0 SE Compact stranded aluminum wire." My 30A/120v inlet calls for 10-2. I reached out to the supplier and they said it will not support 8 gauge wire. If it will fit 8 gauge wire I should be able to run cleanly from inlet to panel, but if not can I run the 10-2 romex from the inlet into the load center, then an inch or so into the panel, pigtail the hot to two 8 gauge wires and connect those to the hot bars to get the minimum thickness required by the load center and act as a jump, and pigtail the neutral from the 10-2 to 8 gauge for the neutral bar? Or, alternatively, can I run 10-2 wire from the inlet to a junction box below the panel and connect the 10-2 inlet wires (10-2 hot wire pigtailed to two 8 gauge hots, 10-2 neutral and ground to 8 gauge neutral and ground) to run up into the panel?

Aha! I didnt realize the need for a main disconnect. I have not yet learned what that entails (main disconnect, tiedown, jumpers, etc), I will have to look into it, thank you for bringing it to my attention. Always more to learn! Is the main disconnect basically an additional 1 pole 30A breaker that is installed first in the subpanel and connected with the tie down to the first 20A breaker?

My plan is to have the entire electrical system on 120V - the inlet is rated for 120V and only has room for one hot wire. From what Ive learned, wiring the sub panel with one hot wire would make it so that only half of the breakers are operational, unless I pigtailed/jumped the hot wire to both lugs. This might be what you were recommending in your post? If I dont jump/pigtail, would that lead to load balancing issues? If I dont jump/pigtail the hot, I imagine I would only have 3 spaces (half of the 6), which could be another reason to upgrade to the 8 space panel. Would you recommend moving forward with only using half of the breakers, or with jumping/pigtail to get power to both sides of the box?

Good call on using conduit in case of a future upgrade. I will look into sourcing that and how to install it. I see

this 1/2" flexible PVC conduit, I imagine I could just order some of this and a few 1/2" strain reliefs for where it connects up to the panel? Then I could always upgrade the wire, or just run #8 romex in the conduit to begin with.

Phew!! More to look up, thank you!