Hello,

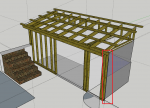

My new home had a 3 sided block outbuilding. THe roof was 3/8" plywood that was falling apart. My initial plan to just re-roof has turned into a fully enclosed shed build. I have framed the front wall and secured 2x6 top plates along the top of the block walls, adding sill seal foam between the block and lumber. The front wall framing is fastened to a bottom plate fastened to the concrete slab using Ramset fasteners. I plan to use LP Smartside panels as siding and will add flashing around the bottom running 4" underneath the siding.

My question is how to bridge the gap at each end of the wall between the wood framing and block wall. I was thinking I could nail flashing to the lumber and then use construction adhesive to secure it to the block and then add sealant to the edge. A trim board will then be installed on the outside of the flashing, leaving a small amount of flashing exposed where it meats the concrete. Is this a good plan?

I have also seen situations where a tape sealant/flashing is used. Would this be a better option? or place this under the metal flashing?

Thanks!

My new home had a 3 sided block outbuilding. THe roof was 3/8" plywood that was falling apart. My initial plan to just re-roof has turned into a fully enclosed shed build. I have framed the front wall and secured 2x6 top plates along the top of the block walls, adding sill seal foam between the block and lumber. The front wall framing is fastened to a bottom plate fastened to the concrete slab using Ramset fasteners. I plan to use LP Smartside panels as siding and will add flashing around the bottom running 4" underneath the siding.

My question is how to bridge the gap at each end of the wall between the wood framing and block wall. I was thinking I could nail flashing to the lumber and then use construction adhesive to secure it to the block and then add sealant to the edge. A trim board will then be installed on the outside of the flashing, leaving a small amount of flashing exposed where it meats the concrete. Is this a good plan?

I have also seen situations where a tape sealant/flashing is used. Would this be a better option? or place this under the metal flashing?

Thanks!