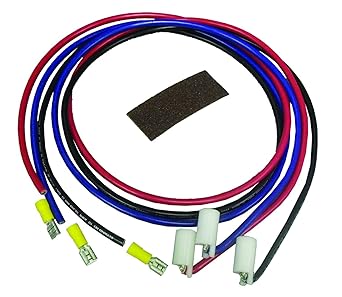

Last year this forum helped me diagnose my heat pump style pool heater. I think I have the same problem but wanted to double check. The fan goes on but not the compressor. Based on comments from last year neither the large or small copper tubes inside the heater are hot or warm which I guess confirms the compressor not running. The fix last year was replacing the capacitor with what appears to be a generic one. Someone said the capacitor was about $40. My question is does it make sense to gamble and try to replace the capacitor again? The technician last year charged over $360. If so where do u get one and now that it was replaced with this generic one do I have to match the exact ones so I can attach the wires exactly as they are? Pictures attached.

I appreciate any help.

Thanks,

Art

I appreciate any help.

Thanks,

Art