There is a code compliant solution to this problem:

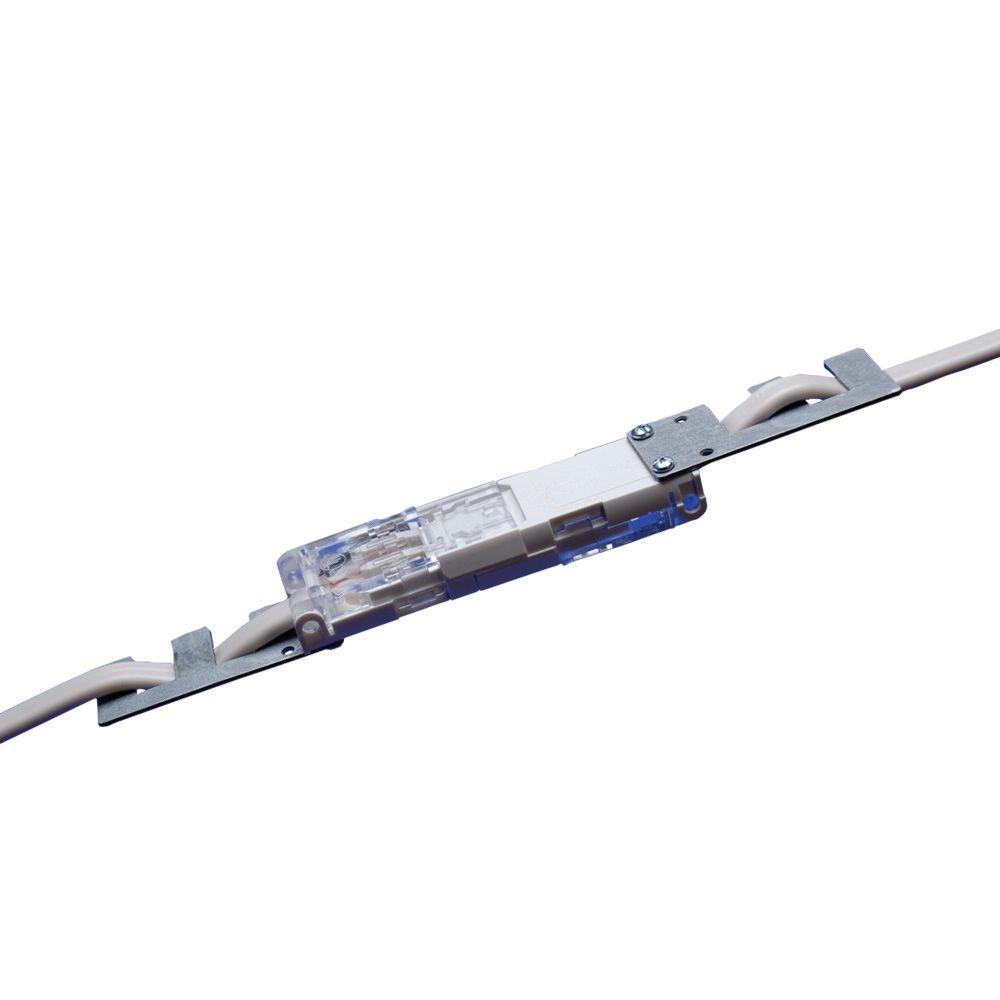

https://www.homedepot.com/p/Tyco-Electronics-Romex-Splice-Kit-2-Wire-1-Clam-A22899-000/202204326 These NM cable splice kits are UL listed for use inside an enclosed wall.

Here is the item that

@mpoulton speaks of:

Here's my nickles worth. I can't say anything else about the work done by the idiot you hired or the work they did that hasn't been said before. Well I could, but this is an open forum. :devil3:

As to how to resolve it.

First, call your appropriate housing authority (Usually the people who gave you your permit. You did pull a permit didn't you?) to report the electrician and to have an inspector come out. If you didn't have a permit, ask if they have their building codes published on-line, including electrical codes.

I am sure that most, if not all, of us would tell you to get a permit pulled for the work being done. If there were a fire in the house at any future time, and it was determined that the wiring that you had hired to do was the cause. Then the contractor would be responsible for cost of the repairs. If you can find him, if not then you. However, if it has passed inspection, then the liability passes of to the inspector and the local housing authority.

I see that you are doing a lot of remodeling work, where is the cable coming from, above or below? Is it possible to put a large junction box there to make the correct connections and then run new cable to the new locations? You could use the cable that the "moron" used. If it is too short, then you can use another junction box to extend the cable. (As long as it is not hidden of course.

If you decide to use the item that

@mpoulton pointed out, check the electrical code that your AHJ uses (you asked about it earlier or that you searched for) and check to see if they have made any changes regarding NEC Code - article 334-40b, 2005 and 2008 NEC. As long as they don't say anything about it, then you are okay to use it. Even if your local inspector may not like it. Although they are the final say about it.

The TYCO unit is only a splice, not a splitter. It is hard to see, but it looks like there may be some cable splitting in that mess. Use the TYCO splice and then run the cable to a point where you can use a junction box to make a safe cable split. I like to add an outlet because you always use more outlets.

Sorry for the long post. There is just so much wrong with this situation that I felt the need to include as much information as possible.

Dan

![Image]()

![Image]()